I find that I spend too much time ensuring that I get every speck of support material off the print plate long after I’ve removed the actual print.

When it comes to the skirt, I always set it to be two layers tall for this exact reason, and I was hoping it’s possible to do the same with the support base.

EDIT: PETG on textured printsheet

3 things that help me with PETG when it comes to separate it from the plate:

- Glue (yes, really)

- Cooling it off (sometimes putting the plate with leftovers on the freezer)

- Olfa scraper (at a right angle to not scratch the plate)

Oh dude, glue stick 100%. PETG is my preferred print material, wouldn’t dream of printing without the glue stick.

Use a smooth plate as well.

I accidentally got such good adhesion with the prusa smooth plate and PETG that I ripped the PET(?) lining off the plate

Exactly what I’m talking about, this is why I’m using glue. If you’re talking about a textured plate it’s probably PEI

I’m actually using spray glue (3dlac) usually with a textured PEI (rarely a smooth PEI) plate. I’m also using PET/PEO (double sided) plate with PETG (without glue) - adhesion is really good, but not too good (so it’s easy to clean).

I actually use a cake knife. No hard edge and it helps lift prints easily. Plus they come in all sizes for larger prints.

Never had to use glue. Just soap and water then wipe down the plate. Also have a dryer (got the crealty one) and made sure it’s hella dry(14% is what I print at) then run my bed at 90c and the nozzle temp at 248. Haven’t had issues since I did that.

Yeah, I dry my filament (especially PETG) with one of those too. I don’t have to use glue, it just makes PETG easier to remove from the plate. Otherwise it can stick to the plate too well (had a case where I removed the model with some of the PEI coating).

Ah so you’re using it as a removal agent vs a sticking agent. That’s interesting. I am using the stock mk3s plate and recently bought a textured plate. I haven’t had any issues with stuff sticking yet, but I haven’t printed anything that has a large area on the bed. Everything I stand up, although I’m experimenting with lithophanes and that’s giving me a whole new level of pain in the ass to deal with.

You don’t want multiple layers as it will lift and cause adhesion issues. The action of heating and letting it cool once is stressful enough on the material. When you create a second heating, while there is a temperature gradient present already, that will create the stress that lifts edges.

Really dial in your first layer settings. The hack is to just use elephant’s foot for the first layer, but you are not actually dialing in your flow and squish. If you take the time to dial in the first layer well, your supports base layer removal should improve. It is possible to get a first layer printing like glass.

Also, you may have a setting to increase the bed probe resolution. That may help if the first layer is not even.

What material and what kind of plate? PEI textured plate or smooth plate? PLA, PETG, something else?

PETG on textured plate.

Yeah, that makes sense for your frustration. I get stabbed under my fingernails trying to take PETG remnants off the textured beds. I typically just deal with it because the solutions I’ve found are more time-consuming, but I guess it might depend on how much.

I’ve had people suggest heating the bed as high as it will go. PETG’s glass transition temperature is usually less than 90° C. I’ve seen some people print over bits to try to merge them to make them pull up easier, but that just seems like a waste of material to me. I generally don’t care for solutions that involve applying liquids or gels to the bed.

If you can’t find what you are looking for, try using blue painters tape or glue stick

@neidu3 Looks like this is an open feature request

https://github.com/prusa3d/PrusaSlicer/issues/9448Ah, so it’s not just me being unable to find a relevant setting, then.

I figured there ought to be a setting for support and brim, as there’s a similar setting for the skirt.

petg on texture without glue?

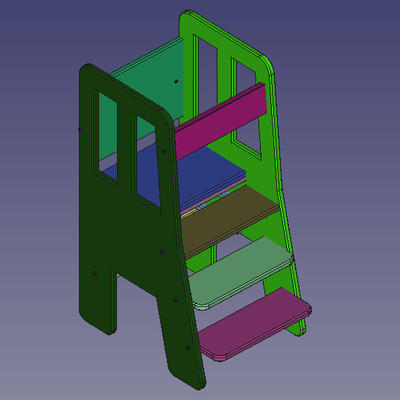

This looks like a small print, suitable for experimenting. Try tilting it 45 degrees so that it is tilted against the bed. It won’t have much contact to the bed but may need way less support and the layers may even strengthen the print.

I’d tilt it so that the flat backside faces towards the bed but do try various versions, see how it goes and also evaluate strength

Edit: oh… Hadn’t seen the frame around it 🤦